Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T,D/P

Transportation: Ocean,Land,Air,Express

Model No.: ASTM A213 S30403

Brand: YUHONG

Status: New

Warranty Period: 3 Months

Applicable Industry: Hotels, Building Material Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Farms

Out-of-warranty Service: Video Technical Support, Online Support

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Types Of Parts: Finned Tube

Standard: ASTM A213

Thickness Of Plain: 0.5mm To 2.0mm

Tube O.D.: ASTM A213 S30403

Corrugation Pitch: 3mm To 10mm, Or Other

Corrugation Depth: 0.5mm To 1.2mm, Or Other

Length: As Per Customer Requirement

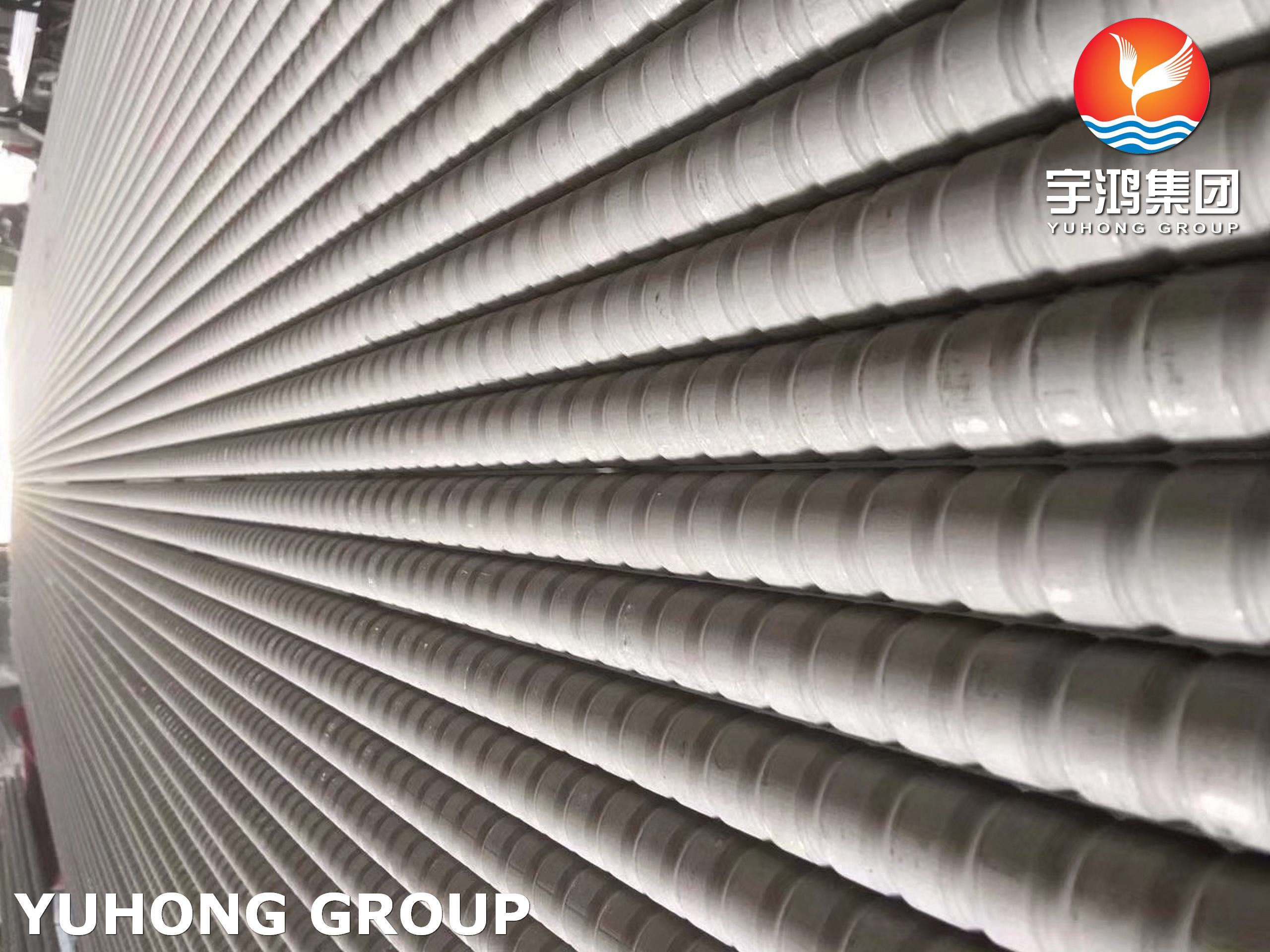

ASTM A213 S30403 Corrugated Tube For Hight-Temperature And Pressure Systems

ASTM A213 S30403 is a specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. It is specifically designed for high-temperature and high-pressure systems.

Corrugated tubes are tubes that have a series of parallel ridges and grooves on their outer surface. These ridges and grooves provide additional strength and flexibility to the tube, making it suitable for applications where high-pressure and high-temperature conditions are present.

The use of corrugated tubes in high-temperature and high-pressure systems helps to improve the overall performance and reliability of the system. The corrugations in the tube help to increase the surface area, which in turn enhances heat transfer efficiency. This is particularly important in applications such as boilers and heat exchangers, where efficient heat transfer is crucial for optimal system performance.

ASTM A213 S30403 corrugated tubes are made from stainless steel grade S30403, which is a low-carbon variation of the popular grade 304 stainless steel. This low-carbon variation offers improved resistance to intergranular corrosion, making it suitable for high-temperature applications.

In summary, ASTM A213 S30403 corrugated tubes are designed for use in high-temperature and high-pressure systems. These tubes provide enhanced strength and flexibility, improving heat transfer efficiency and overall system performance.

ASTM A312 Stainless Steel 304L Pipe Grade Specifications

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS |

| SS 304L | S30403 | 1.4306/1.4307 | Z3CN18‐10 | X5CrNi18-10 | SUS 304L | 304S11 |

Stainless Steel 304L Pipe Chemical Composition

| Grade | P | Ni | Si | N | C | |

| 304L | min. | - | 8 | - | - | - |

|

| max. | 0.045 | 10.5 | 0.75 | 0.1 | 0.08 |

Stainless Steel 304L Pipe Fittings Mechanical properties

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

|

|

|

|

| Rockwell B (HR B) max | Brinell (HB) max |

| 304L | 485 | 40 | 170 | 92 | 201 |

The production process of corrugated tubes involves several steps:

1. Material selection: The first step is to select the appropriate material for the corrugated tube. Common materials used include plastic, metal, or rubber, depending on the specific application and requirements.

2. Extrusion: The selected material is then fed into an extruder, which heats and melts the material. The molten material is then pushed through a die, which gives it the desired shape and size of the corrugated tube.

3. Corrugation: After extrusion, the tube is passed through a set of corrugating rollers. These rollers have a series of teeth or ridges that press into the tube, creating the characteristic corrugated pattern. The corrugation process strengthens the tube and provides flexibility and rigidity.

4. Cooling and cutting: The corrugated tube is then cooled to solidify the material and set the shape. Once cooled, the tube is cut into the desired length using a cutting machine.

5. Finishing: After cutting, the corrugated tubes may undergo additional finishing processes, such as trimming the edges or applying surface treatments for added protection or aesthetics.

6. Quality control: Throughout the production process, quality control measures are implemented to ensure that the corrugated tubes meet the required specifications and standards. This may involve visual inspections, dimensional checks, and testing for strength, flexibility, and other performance characteristics.

7. Packaging and distribution: Once the corrugated tubes have passed quality control, they are packaged and prepared for distribution to customers. The tubes may be bundled, boxed, or wrapped in protective material to prevent damage during transportation.

The production process of corrugated tubes involves material selection, extrusion, corrugation, cooling and cutting, finishing, quality control, and packaging. This process ensures that the tubes are manufactured to the required specifications and are ready for use in various applications, such as electrical wiring, plumbing, automotive, and industrial systems.

Corrugated tubes have a wide range of applications in various industries. Some of the common applications of corrugated tubes include:

1. Plumbing and drainage systems

2. Electrical conduit

3. Automotive industry

4. HVAC systems

5. Medical and pharmaceutical industry

6. Agriculture

7. Packaging industry

8. Industrial machinery

9. Telecommunications

Packaging: Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Productivity: 1000 Tons Per Month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: According To Client's Request

Certificate: ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015

Port: Ningbo Port,Shanghai Port,Tianjing Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW,Express Delivery

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.