Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T

Transportation: Ocean,Land,Air,Express

Model No.: ASME SA179

Brand: YuHong Group

Status: New

Applicable Industry: Manufacturing Plant, Construction Works, Building Material Shops, Other

Out-of-warranty Service: Online Support

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Service System: Online Support

Product Name: Carbon Steel Fin Tube

Tube Specification: ASME SA179

Fin Material: Aluminum 1060

General Tube Material: Carbon Steel,Stainless Steel,Alloy Steel

General Fin Material: Aluminum,Copper,carbon Steel

Fin Height: <17mm

Fin Thickness: 0.2mm-0.4mm

Fin Pitch: 1.6mm-10mm

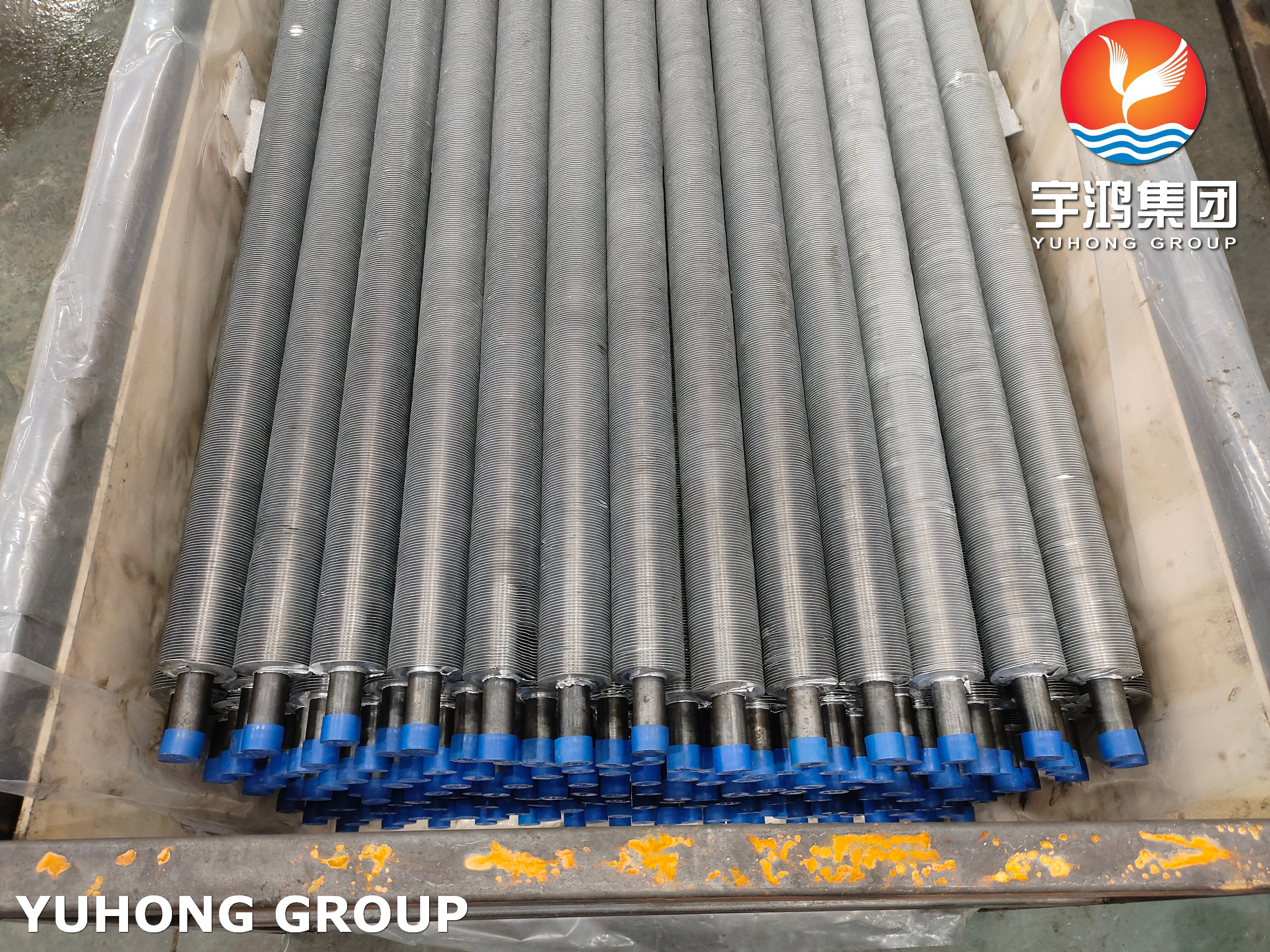

ASME SA179+Al1060 Carbon Steel Extruded Fin Tube For Heat Exchanger Application

What are extruded fin tubes?

Extruded fin tubes are a type of Heat Exchanger Tube that has fins formed directly on the tube surface through an extrusion process. These fins increase the surface area of the tube, allowing for enhanced heat transfer between the fluid inside the tube and the fluid outside.

How are extruded fin tubes produced?

The extrusion process involves pressing or forcing a metal or alloy through a shaped die to create the fins on the tube surface. This results in fins that are tightly bonded to the tube, providing good thermal contact and efficient heat transfer. Aluminum is commonly used for extruded fins due to its excellent thermal conductivity and corrosion resistance.

Extruded fin tubes are a popular choice for heat exchangers due to their high thermal efficiency and durability. These tubes are manufactured by extruding fins onto the outer surface of a base tube, creating a larger surface area for heat transfer. The fins can be either solid fins or serrated fins, depending on the application and desired performance.

Extruded fin tubes material:

Extruded fin tubes are available in a variety of materials, including carbon steel, stainless steel, copper, and aluminum. The choice of material depends on the specific application requirements, such as temperature, pressure, and corrosive environment. The manufacturing process allows for customization of the fin geometry and spacing, enabling engineers to design tubes that are optimized for their intended use.

Chemical Composition for A179:

| Grade | C | Si | Mn | P | S |

| A179 | 0.06-0.18 | 0.25 max | 0.27-0.63 | 0.035 max | 0.035 max |

Mechanical Properties for A179:

| Tensile Strength (Mpa), min | Yield Strength (Mpa), min | Elongation (%), min | Hardness (HRB), max |

| 325 | 180 | 35 | 72 |

Extruded fin tubes advantages:

1. Enhanced heat transfer: The fins significantly increase the surface area available for heat transfer, improving the overall heat transfer efficiency of the heat exchanger.

2. Compact design: By increasing the surface area, extruded fin tubes allow for compact heat exchanger designs, which is particularly beneficial in applications with space constraints.

3. Improved heat transfer coefficient: The design of extruded fins promotes better fluid mixing and turbulence, leading to a higher heat transfer coefficient and improved heat exchange performance.

4. Resistance to fouling: The extruded fins create turbulence and disrupt the boundary layer, reducing the likelihood of fouling by preventing the accumulation of debris or deposits on the tube surface.

5. Extruded fin tubes are their resistance to corrosion and erosion. The fins protect the base tube from exposure to corrosive materials, prolonging the life of the tube and reducing maintenance costs. Additionally, the fins can help to reduce fouling by preventing the buildup of deposits on the tube surface.

6. Extruded fin tubes are their ability to withstand high temperatures and pressure. They are commonly used in applications such as power generation, petrochemical processing, and air conditioning systems. The fins provide increased heat transfer surface area, which allows for more efficient heat transfer and reduced energy consumption.

Overall, extruded fin tubes offer excellent thermal performance, compact design, and resistance to fouling, making them a popular choice for heat exchanger applications requiring high heat transfer efficiency.

Extruded Fin Tube's Applications:

-Pharmaceutical Equipments

-Chemical Equipments

-Sea Water Systems

-Heat Exchangers

-Condensers

-Pulp and Paper Plants

-Power Generation

-Gas Processing Plants

-Chemicals Industries

Packaging: Ply-Wooden Cases with Iron Frames

Productivity: 100 Tons Per Month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: According to Client's Requirements

Certificate: ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015

HS Code: 8419909000

Payment Type: L/C,T/T

Incoterm: DDU,FOB,CFR,CIF,EXW,CIP,Express Delivery

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.