Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T

Transportation: Ocean,Land,Air,Express

Model No.: ASME SA179

Brand: YuHong Group

Status: New

Warranty Period: 3 Months

Applicable Industry: Construction Works, Manufacturing Plant

Out-of-warranty Service: Online Support

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Tube Specification: ASME SA179

Fin's Material: Aluminum 1060

Fin Height: <17mm

Fin Thickness: ~0.4mm

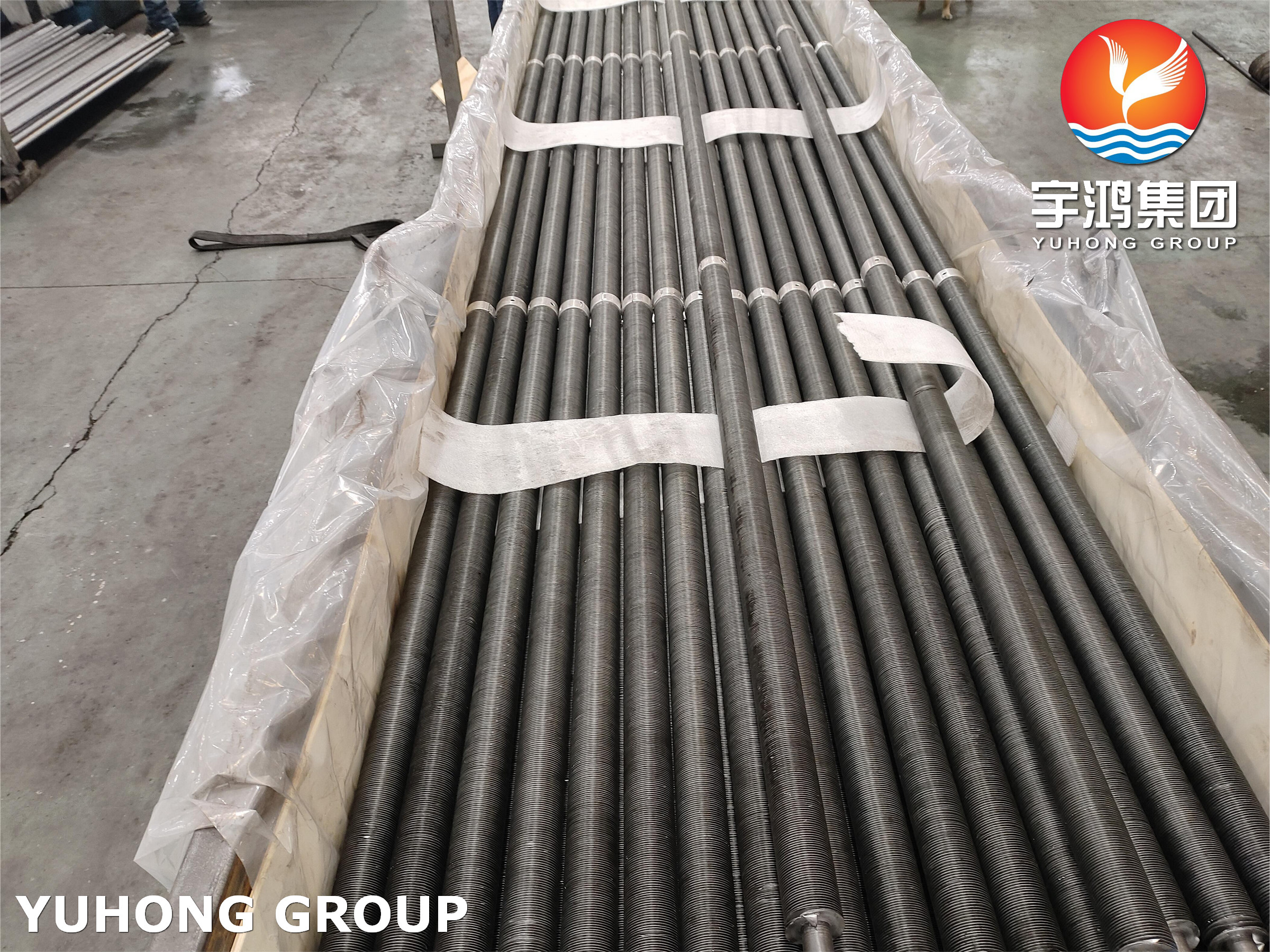

Product Name: Carbon Steel Embedded Fin Tube

Fin Type: Embedded/G-Fin

ASME SA179+AL1060 Carbon Steel Embedded G-Type Fin Tube For Heat Exchanger Application

What is G Type Finned Tube?

G type embedded spiral finned tube is processed from a certain width in the steel pipe and spiral groove depth, then inlays the ribbon on the steel pipe by the equipment. In winding process, as the pre-tightening force to a certain extent so the strip will be firmly in the spiral groove, to ensure there is a certain contact area between steel band and steel pipe. In order to prevent the strip spring falling off the light tube, the two ends of the steel strip need to weld onto the steel pipe. In order to set easily, there should be a certain clearance between steel belt and spiral groove. If the clearance is too small the setting process will be difficult to proceed smoothly. In addition, the steel belt of winding there will always be a certain amount of rebound, which makes it cannot very good joint among the steel belt and spiral groove bottom. Inlaid fins can be conducted on general equipment, and they cost little.

What are SA179 embedded fin tubes?

Embedded fin tubes can be manufactured using SA179 carbon steel tubes as the base material. In the case of SA179 embedded fin tubes, the fins are inserted or embedded into grooves on the outer surface of the tube. This type of fin tube is designed to increase the heat transfer surface area and enhance the heat exchange efficiency.

The embedded fins are typically made of materials such as aluminum or copper. They are tightly fitted into the grooves on the SA179 carbon steel tube, ensuring good thermal contact between the fins and the tube. This allows for efficient heat transfer between the fluids flowing inside the tube and the surrounding medium.

Chemical Composition of A179

| C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Mechanical properties of A179

| Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | Hardness(HRB) |

| 325 Min | 180 Min | 35 Min | 72 max |

What are the characteristics of G-fin tubes?

-The heat transfer characteristics of G-fin tubes are related to the contact thermal resistance between the Finned Tubes, and the core of the contact thermal resistance is the contact pressure between them. Obviously, the heat transfer characteristics of welded chips and sleeves are better, followed by bimetallic pipes, with poor insertion and winding. After re curling, the contact area of the KLM finned tube increased by about 50% and was not affected by the outer diameter tolerance of the tube. After multiple cold cycles, the contact is good, the contact thermal resistance is small, and the heat transfer characteristics are high. The slotted finned tube can increase the disturbance of air flow and increase the total heat transfer coefficient by about 20%.

-As the wall temperature of the G-fin tubes with room temperature performance increases, the contact pressure between the pin and the tube changes, and the contact thermal resistance also changes. The fluctuation value depends on the type of finned tube and the initial contact pressure. As the temperature increases, the pin tension around the chip rapidly decreases, resulting in a rapid increase in contact thermal resistance. Bimetal rolling can maintain stability over a wide temperature range.

-The bare tube of the G-fin tubes is protected by the wing to prevent atmospheric corrosion. Due to different protection ranges, the ability of various types of finned tubes to resist atmospheric corrosion also varies. Among various finned tubes, bimetallic rolling is good. All finned tubes that have undergone hot-dip galvanizing treatment have good atmospheric corrosion resistance. Chemical plants with corrosive gases in the atmosphere should pay special attention to the selection of raw materials and types of finned tubes, as aluminum needles are prone to corrosion.

-In many operations of finned tubes, pressure is the material and wall thickness selected in the bottom tube, but it is also related to the type of finned tube. Rolling (bare tube made of aluminum copper material) has low pressure resistance and is not suitable for use in air coolers. The bottom tube of the embedded chip has a rolling groove, and the working pressure decreases with the increase of working temperature.

-Clean the dirt on the gas side of the dirty G-fin tubes, usually using compressed air, steam, or high-pressure water. In this way, the fins have corresponding stiffness.

-Manufacturing costs. From the perspective of raw material consumption of G-fin tubes, the circumference is low and the bimetallic rollers and sleeves are high. The consumption of bimetallic aluminum rolling is 1/3 to 1/2 more than that of wrapping. From the perspective of production and processing costs, the circumference is lower, the bimetallic rolling is higher, and the sleeve is higher. All finned tubes that require surface hot-dip galvanizing are relatively expensive in terms of raw material consumption or manufacturing process.

SA179 embedded fin tubes advantages:

The finned surface of the SA179 fin tube increases the surface area of the tube, which in turn increases the heat transfer rate. This design allows for efficient heat transfer even in applications where there is limited space for heat exchange. The embedded fins are tightly secured to the base tube, ensuring that they remain in place even under extreme conditions.

In addition to its high heat transfer efficiency, the SA179 Embedded Fin Tube is also easy to install and maintain. Its design allows for easy cleaning and inspection, reducing downtime and maintenance costs. The tube is also compatible with a wide range of fluids and gases, making it versatile and suitable for a variety of applications.

Application: Mainly used in petrochemical, electric power, paper, tobacco, building heating and other industries such as air cooler, air heater and food industry plant protein powder, starch and other spray drying system of air heaters.

Packaging: Ply-Wooden Cases with Iron Frames

Productivity: 100 Tons Per Month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: According to Client's Requirements

Certificate: ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008

HS Code: 8419909000

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,CIP,DDU,Express Delivery

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.