Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T

Transportation: Ocean,Land,Air

| Material | |

| Types | |

| Contact Now |

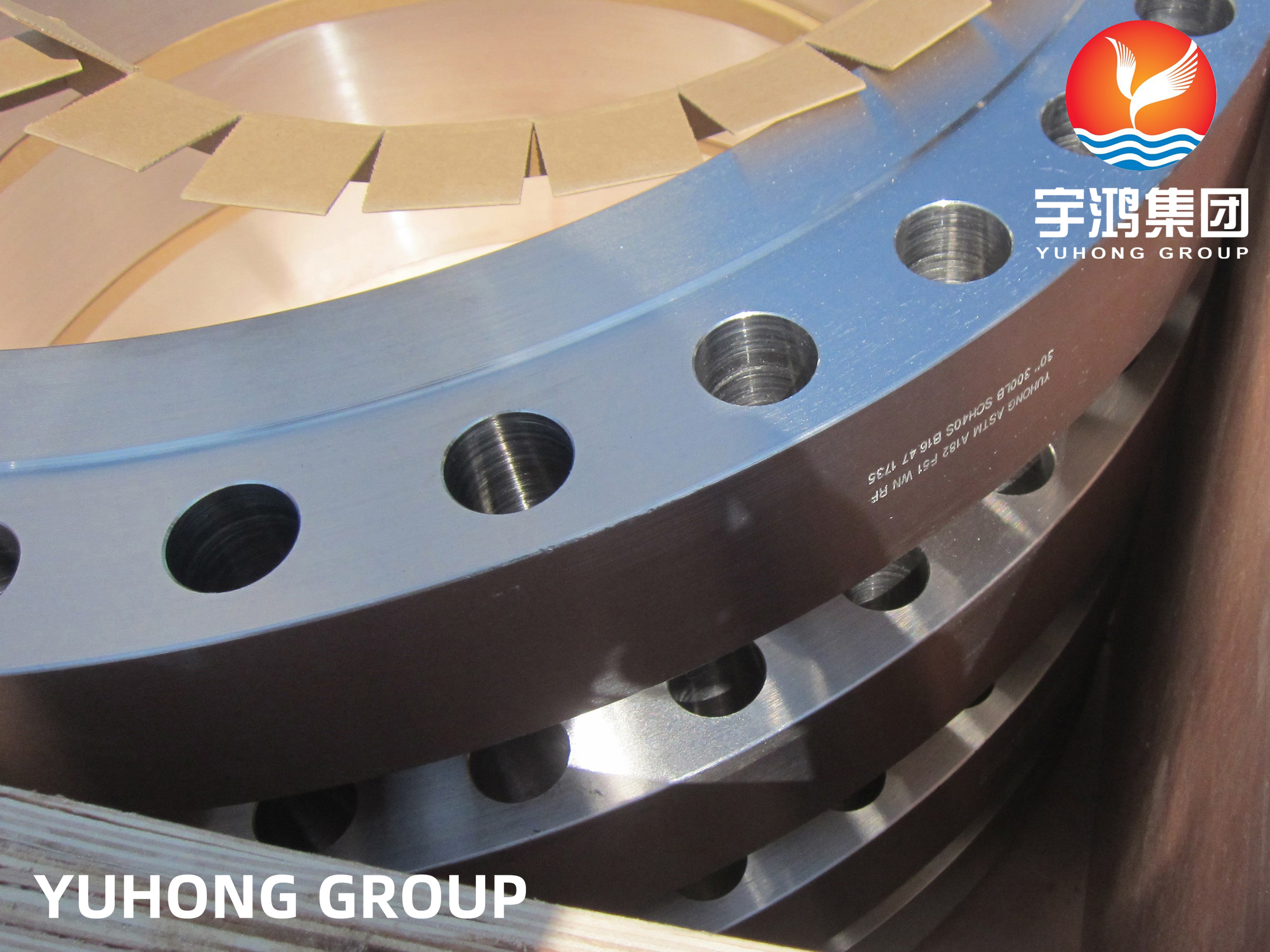

Model No.: ASTM A182 F51

Brand: YUHONG

Place Of Origin: China

Specifications: ASTM A182, ASME SA182

Standards: B16.5

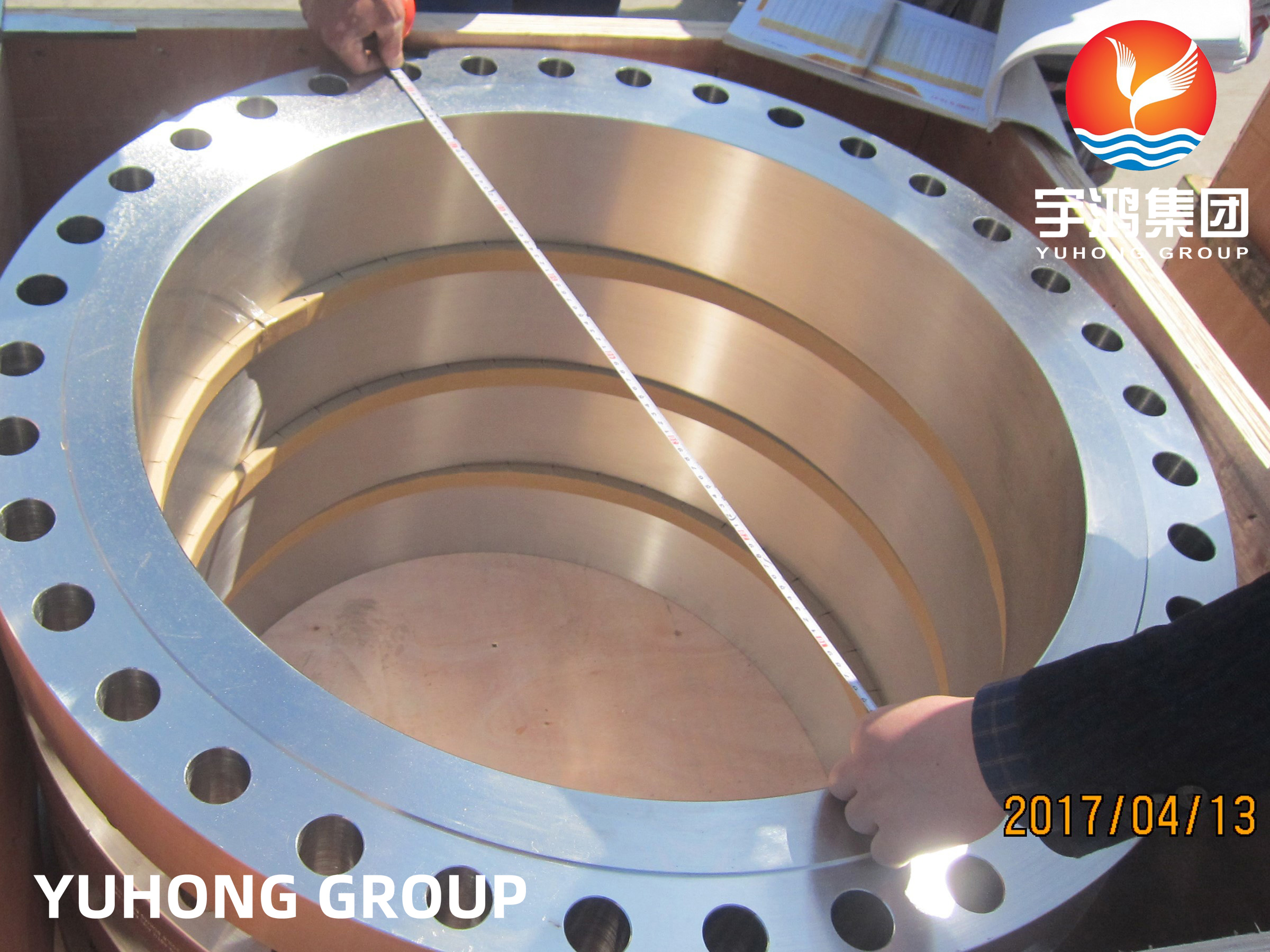

Type: Weld Neck

Connect: Raised Face (RF)

Material: S31803

ASTM A182 F51 Duplex Stainless Steel Welding Neck Flange

ASTM A182 F51 is a duplex stainless steel grade that offers excellent corrosion resistance and high strength. It is commonly used in industries such as oil and gas, chemical processing, and marine applications.

It is important to consult the welding procedure specification (WPS) provided by the manufacturer or a qualified welding engineer for specific guidelines on welding ASTM A182 F51 duplex stainless steel welding neck flanges. Following the recommended procedures and using qualified personnel can help ensure the quality and performance of the welded joints.

| Outside Diameter | Inside Diameter |

| ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm | not applicable |

| Diameter of Contact Face | Outside Diameter of Hub |

| 1.6 mm Raised Face = ± 0.8 mm | ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

|

| Diameter of Counterbore | Drilling |

| not applicable | Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm |

|

| Eccentricity of Bolt Circle with Respect to Facing |

|

| ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness | Length thru Hub |

| ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 | ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

| C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Application

Packaging: Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Productivity: 1000 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: According To Client's Request

Certificate: ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015

HS Code: 7307210000

Port: Ningbo Port,Tianjing Port,Shanghai Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.