Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: T/T,L/C,Western Union

Transportation: Ocean,Land,Air

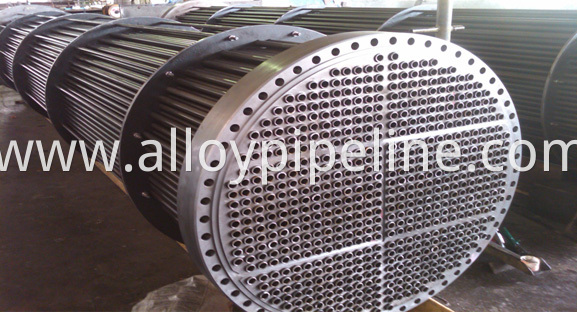

Model No.: Heat Exchanger Tube Super Duplex S32760 ASME SA789

Brand: YUHONG

Detailed Product Description

S32760 Duplex Stainless Steel Tubes/Pipes ASTM A789, ASTM A790 / ASTM 928 / ASTM A999

Specifications Of Alloy S32760

|

Applications Of Alloy S32760

| Chemical Process Industry: |

| Nitric Acid Processes, Polypropylene Production, PVC Production, Dioxide, Caustic Evaporators, Equipment |

| Handling Organic and Fatty Acids |

| |

| Marine Industry and Shipbuilding: |

| Propellers and Shafts, Rudders, Shaft Seals, Pumps, Bolts and Fasteners, Valves, Instrumentation, Oil and Chemical Tankers |

| Oil and Gas Industry: |

| Pumps, Valves, Pipe, Vessels, Wellhead Equipment, Subsea Equipment |

| Pollution Control: |

| Fans and pumps, Wet Scrubbers, Incinerators |

| Pulp and Paper Industry: |

| Black liquor heater tubes, Digester Blow Valves, Rotary Feed Valves, I.D.Fans, Brownstock Washers, Precipitators, Bleaching Components |

| Food Industry: |

| Sugar Cane Centrifuges, Corn and Vegetable processing plant |

| Agrochemicals: |

| Fertiliser Production (Wet phosphoric acid) |

| Civil Engineering: |

| Sewage Treatment |

Alloy S32760 Features

|

Key Features Of Alloy S32760

|

| Elements | C | Cr | Cu | Fe | Mo | Mn | N | Ni | P | S | Si | W |

| Minimum | 24.0 | 0.5 | REMAINDER | 3.0 | 0.20 | 6.00 | 0.50 | |||||

| Maximum | 0.030 | 26.00 | 1.0 | 4.0 | 1.0 | 0.30 | 8.00 | 0.030 | 0.010 | 1.00 | 1.00 |

Basic Properties Of Alloy S32760 - Mechanical Properties

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 550 [79.8] |

| Ultimate Tensile Strength (N/mm2) [ksi] minimum | 750 [108.8]] |

| Elongation (%) minimum | 25 |

| Hardness (HBN) | 270max |

| Reduction of Cross Section Area (%) minimum | 45 |

| Charpy V-notch Impact at ambient Temp (J) [ft.lb] | 80min [59min] |

| Charpy V-notch Impact at -46°C (J) [ft.lb] | 45av, 35min [33av, 25.8min] |

| Additional Testing | |

| ASTM G48A Corrosion test at 50°C | No pitting and weight loss <0.8g/m2 |

| Ultrasonic Testing | According to ASTM A388 |

| Ferrite Content | 35%-55% |

| Microstructure | Microstructure certified free from grain boundary carbides, sigma, chi and laves phases |

| Alloy | Common Name | Related Specifications | Tensile Strength | Proof Stress | Elongation | ||

|---|---|---|---|---|---|---|---|

| British | European | United States | |||||

| Super Duplex Alloy S32760 | Zeron 100 | 1.4501 | UNS S32760 | F55 | 750 [109] | 550 [79.8] | 25 |

Yuhong Holding Group Co.,Limited is one of the largest Procurement Engineering and Contracting Group companies in China. Our group branch company and factory have been already approved by : ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004. Yuhong Holding Group has expanded its field of activit...

| Selling Units | : | Kilogram |

|---|---|---|

| Package Type | : | Ply-wooden Case /Iron Case with plastic Cap |

Packaging: Ply-wooden Case /Iron Case with plastic Cap

Productivity: 800 Tons Per Month

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: PED, TUV, DNV, ABS, COST, TS , ISO

Payment Type: T/T,L/C,Western Union

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.