Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T,D/P

Transportation: Ocean,Land,Air,Express

Brand: YUHONG

Standard: Gb, Astm, Jis, Din

Section Shape: Round

Application: Boiler Pipe

Production Process: Cold Rolled

Special Tube: Thick Wall Pipe

Whether Alloy: Is Alloy

Tolerance: ±10%

Category: Seamless Steel Pipe

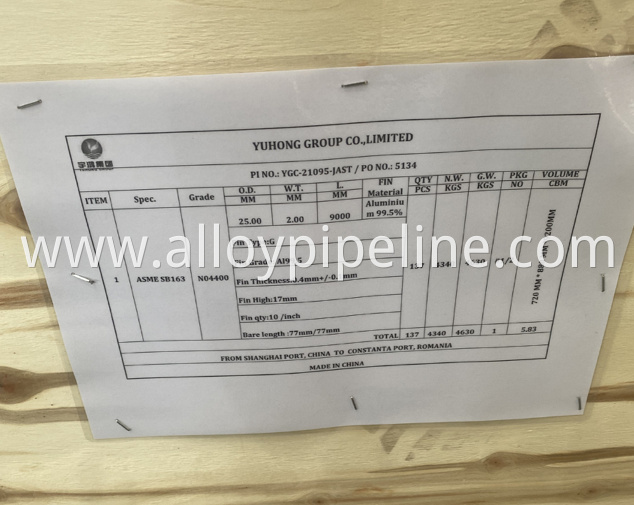

ASTM A335 P11 Studded Fin Tube

ASME SB163 UNS N04400 Monel 400 tube is one kind of Nickel Base Alloty Seamless Tube For Heating.

ASTM B163, B165 ASME SB163, SB165 NACE MR0175 Nickel Alloy Pipe Monel 400 / EN 2.4360 / Monel K500 / 2.4375

Monel 400®, Nickelvac® 400, Nicorros® 400

Monel 400 is a combination of nickel and copper and is hardened by cold working only. This alloy is widely renowned for for its corrosion resistant properties against flowing sea - water and is extensively used for marine applications. Monel is also extremely resistant to stress corrosion cracking in most freshwaters. High temperature ( up to 1000 °F) has no effect on this alloy and it also has excellent mechanical properties at subzero temperatures.

Monel 400 is available in many forms like wire , Round bar, Forged bar , hex bar , Flat bar , Circles , Ring , Tube , seamless Pipe , Welded / ERW Pipe , Sheet , Plate , Coil , Flanges , fasteners , Socket weld Fittings , ferrule fittings , Buttweld fittings Like cap , elbow , tee. UNS N04400 is available in various forms like Monel 400 wire , Monel 400 Round bar, Monel 400 Forged bar , Monel 400 hex bar , Monel 400 Flat bar , Monel 400 Circles , Monel 400 Ring , Monel 400 Tube , Monel 400 seamless Pipe , Monel 400 Welded / ERW Pipe , Monel 400 Sheet , Monel 400 Plate , Monel 400 Coil , Monel 400 Flanges , Monel 400 fasteners , Monel 400 Socket weld Fittings , Monel 400 ferrule fittings , Monel 400 Buttweld fittings Like cap , elbow , tee , Reducer.

UNS N04400 is available in various forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, round bar, seamless pipes, sheet, tee and tube.

Chemical Analysis of ALLOY 400 (UNS N04400)

Monel 400®, Nickelvac® 400, Nicorros® 400

| C | MN | P | S | Si | Cr | Ni | M | Cu | Cb +Ta | Al | Fe | other |

| .25max | 1.5 max | . 01 max | .5 max | 63.0 min | 27-33 | 2.30- 3.15 | 2.5 max |

Specifications

| Monel 400 Sheet / Plate | Monel 400 Round Bar | Monel 400 Pipe | Monel 400 Tube | Monel 400 Fittings | Monel 400 Forgings |

| QQ N 286 | ASME SB-865 AMS 4676 QQ N 286 | QQ N 286 AMS 4676 |

Details as below:

G fin Finning lines: 5 finning machines.

Daily capacity up to 3500 meters.

Tube OD: 50.8mm(2'') max.

Tube Length: 18,000mm max.

Fin Height: 16.5 mm max.

Fin Thickness: generally 0.4mm ~0.6mm

Fin Pitch: 2.1 mm (12FPI) min.

Yuhong's Manufacturing process: The aluminum fin strip is tension wound and placed into a groove cut into the tube with appr. 0.4mm fluted depth.

Surface Protection of Plain Ends

Both ends of Grooved G Type Fin Tubes shall be Zinc or Aluminum metalized applied by an electro spray arc system coating.

Acceptance criteria

API Standard 661(Air-Cooled Heat Exchangers for General Refinery Service) or the delivery conditions (TDC).

Accessories

Yuhong also can supply Tube support box, clamp or spacer box (Materials: Aluminum, Zinc and Stainless Steel) for our clients.

Delivery condition:

Tube ends are square cut, free burrs, internally dried and air blown clean, externally coated with varnish at both ends of G-Fin Embedded Finned Tube.

The desiccants are put into each package for continental transporation as well.

Applications:

The common application fields are:

Specifications:

Grooved G type Finned Tubes are combined with two different materials.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material | Carbon steel, low-alloy steel, stainless steel, brass, copper, cooper-nickel alloys, aluminum bronze, nickel alloys.

| 1. Carbon Steel: A179, A192,SA210 Gr A1/C, A106 Gr B 2. Stainless Steel: TP304/304L,TP316/TP316L/316Ti, A789 S31803/S2205 etc... 3. Copper:UNS12200/UNS14200/UNS70600, CuNi70/30,CuNi 90/10 4.Nickel alloy 600, 601, 625 etc 5.Incoloy alloy: 800, 800H, 800HT, 825 etc 6.Monel 400, K500 etc. |

| Fins Material | 1. Aluminum Alloy 2. Copper. | 1. Aluminum (Alu.1100,Alu.1060) 2. Copper. |

| All dimensions are in Inches and specification upon your requests. | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| Please kindly email us for more information or any firm inquiry. | |||

Our Competitive Advantage:

| Selling Units | : | Kilogram |

|---|---|---|

| Package Type | : | Steel Frame Plywood Case Packing |

Packaging: Steel Frame Plywood Case Packing

Productivity: 600 tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: CHINA

Certificate: ABS, GL, DNV, NK, PED, AD2000, GOST9941-81

Port: Shanghai Port,Ningbo Port

Payment Type: L/C,T/T,D/P

Incoterm: EXW,CIF,CFR,FOB

Yuhong Group Co.,Limited is one of the largest Procurement Engineering and Contracting Group companies in China. Our group branch company and factory have been already approved by : ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004. Yuhong Group has expanded its field of activities and entered in trade and supply of tubular & flat products in Stainless Steel, Carnon steel, Alloy Steel as well as a series of special materials for our reputed clients worldwide. These products are widely used in various important sectors like Mining, Energy, Petrochemical, Chemical Industry, Food Plant, Paper Plant, Gas and Fluid Industry etc.

Yuhong Group has gained rich experience in Pipes, Fittings, Flanges, Valves, Structural steel, Coils and Plates in past seven years. In a short span of time, Yuhong Group has marked its global presence in more than 30 countries. We have successfully implemented the orders of Cross Country Pipelines for our valuable customers. In addition, we have also developed a huge network of contacts and strategic alliances with most important manufacturers an stockists around the world.

It allows us to offer highly competitive solutions with certified quality, complying with high standard of today's industry. In the supply chain of Yuhong Group,Stainless Steel Pipe and Tube, which are produces by our factories : Zhejiang Yuhongwell Steel Co.,Ltd , Zhejiang Zhongwu Tube Manufacturing Co.,Ltd , Jiangsu New Zhongzhou Special Alloy Materials Co.,Ltd etc. And all of other products' suppliers are approved by our QC department. About Stainless Steel Fittings & Flanges, our suppliers are approved by PED, AD2000, DNV, ABS, TS, GL, LR, KR, GOST, NK, etc. Similarly in Carbon steel pipe/tube/fitting, our suppliers are approved by API5L, API 5CT,API 5D, PED etc. When we place the order, it is our practice to follow the order start from raw material. After getting the material ready, our QC people make strict inspection again before loading the material. We will follow the whole processing of producing, marking ,packing and inspection before deliver to customer.

ASTM A335 P11 P22 P9 P91 CARBON STEEL FINNED TUBE FOR HEATER EXCANGER USE

HFW Solid Finned Tubes short for High Frequency Welded Helical Spiral Solid Finned Tube

Helical Finned Tubes provide the designer with high thermal efficiency and compact design solutions for a whole range of heat exchangers where clean flue gases are used. Helical finned Tubes are manufactured in both Solid and Serrated type.

Helical Solid Finned Tubes are manufacturer by helically wrapping continuous fin strip on tube. HF Resistance Welding Usually Employs Frequency Of 400 kHz. The fin wound around the tube And Continuous weld. The fin strip is wounded spirally onto the tube and welded continuously with a high frequency electrical process to the base tube along the spiral root. The fin strip held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the base tube surface. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter, using the gas metal arc welding process.

For a given tube or pipe size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and /or number of fins per meter of length.

HFW Solid Finned Tube

This welded steel finned tube configuration can be used for any practically heat exchanger application, and is particularly suited to high temperature and high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond.

Technical Details/Base Tube Details

Tube Diameter : 20 mm OD Min to 219 mm OD Max.

Tube Thickness : Minimum 2 mm up to 16mm

Tube Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

Fin Details

Fins Thickness : Min. 0.8 mm to Max. 4 mm

Fins Height : Min 0.25” (6.35 mm) To Max.1.5” (38 mm)

Fin Density : Min 43 Fins Per Meter To Max. 287 Fins Per Meter

Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel and Incolloy.

For a rapid quotation, plz send with following requirement:

Number of pieces,

base tube: Diameter, thickness, length and material specification.

Fins: material specification, type (solid or serrated), height, thickness, spacing, finned length and unfinned sections. Weld prep details if required.

Delivery period required.

Keywords: Fin tubes, Finned tube, Finned Pipe Helical Finned Tubes, Solid fin tubes, Serrated finned tube, Helical Serrated Finned Tubes, Tubos Aletados

| *These are the most common fin/tube patterns. We have more than 20 different plate fin and tube combinations. Contact me for more information and options. | ||

|

Helical Fin Surface (Tube OD – Available Helical Fin Height on the Tube) |

||

| 5/8″ – 3/8″, 1/2″ and 7/16″ | 1″ – 3/8″, 1/2″ , 7/16″ and 5/8″ | 1 1/4″ – 3/8″, 1/2″ , 7/16″ and 5/8″ |

| 15.875mm – 9.525mm, 12.7mm and 11.113mm | 25.4mm – 9.525mm, 12.7mm, 11.113mm and 15.875mm | 31.75mm – 9.525mm, 12.7mm, 11.113mm, and 15.875mm |

|

||

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.