Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Categories

Send Inquiry

Payment Type: L/C,T/T

Transportation: Ocean,Land,Air,Express

Model No.: ASME SB171 C46400&ASME SB C71500

Brand: YUHONG

Status: New

Applicable Industry: Construction Works, Manufacturing Plant, Energy &Amp; Mining

Out-of-warranty Service: Online Support

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Use: Heater Parts

Product Name: Copper Alloy Steel Baffle Plate

Specification: ASME SB171

Material: C46400&C71500

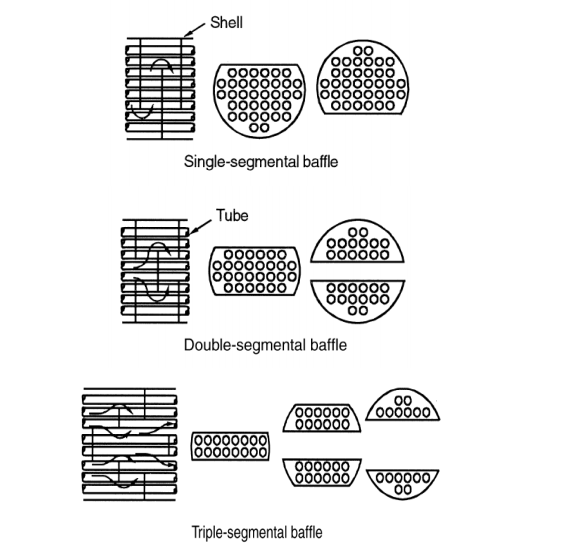

Baffle Type: Single Segmental Baffle;Double Segmental Baffle;Triple Segmental Baffle;Disk And Doughnut Baffles;Orifice Baffles;Rod Baffles

ASME SB171 C46400&C71500 Copper Alloy Baffle Plate for Heat Exchanger Application

What is Baffle Plate?

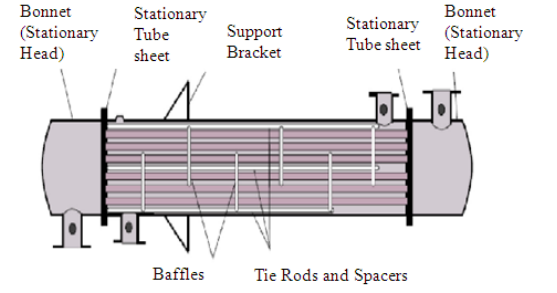

A baffle plate is a device used to modify the flow of fluids or gases within a container or process equipment. It is typically a flat or curved plate that is installed inside a vessel or tank to redirect the flow of fluids or gases, prevent unwanted mixing, or enhance heat transfer.

In process industries, baffle plates are commonly used in equipment such as tanks, heat exchangers, crystallizers, evaporators, and distillation columns to regulate the flow of fluids or gases and improve the efficiency of the equipment. Baffle plates can also be used to increase turbulence and mixing, which can improve heat transfer and reduce fouling.

There are different types of baffle plates, including perforated plates, cut-and-folded plates, and helical baffles. The specific type of baffle plate used depends on the application and the desired fluid or gas flow pattern.

Baffle plates are made from a variety of materials, including metals (such as stainless steel, carbon steel, and aluminum) and plastics (such as polypropylene and PVC). The material used depends on the intended application, including temperature, pressure, and chemical resistance requirements.

In summary, baffle plates are an essential component of many process equipment, used to control the flow of fluids or gases and enhance heat transfer. Their effectiveness can improve the performance, efficiency, and lifespan of various industrial equipment.

What is the minimum baffle spacing recommended?

The minimum baffle spacing recommended depends on the specific application and the type of equipment being used. However, in general, the minimum baffle spacing recommended for most applications ranges between 0.2 and 0.5 times the diameter of the vessel or tube bundle.

For example, in a shell-and-tube heat exchanger, the most common baffle spacing is between 0.25 and 0.35 times the diameter of the shell. In a distillation column, the minimum spacing can range between 0.25 and 0.45 times the column diameter.

It is important to note that the minimum baffle spacing is not the same as the optimum baffle spacing. The optimum baffle spacing depends on several factors, including fluid properties, heat transfer coefficients, and pressure drop. The optimum spacing is the one that provides the best balance between heat transfer efficiency and pressure drop.

The design of baffles should also consider other factors, such as the type and size of tubes or pipes used, the intended flow velocity and turbulence, and the thickness and strength of the baffle material.

In summary, the minimum baffle spacing recommended varies depending on the application and type of equipment. It is important to consult with a specialist in the field to determine the optimal baffle spacing for a specific application.

What is Baffle to Tube Clearance?

Every tube inserted in baffle has a clearance between the tube outside diameter and the baffle hole diameter. This clearance allows the tubes to be inserted in to the baffle with ease. TEMA standards provide clearance optimum requirement values that is employed in industry. These requirements take in to account the spacing that need to be provided fir differential expansion and contraction between baffle plate and tubes. Certain amount of leakage through the clearances is permitted to reduce stagnant regions and to make turbulent conditions more uniform and reduce shell side pressure drop. The leakage also reduces deposits in stagnant areas.

If the clearances are large, it can cause excessive fluid bypassing resulting in fluid starving regions in shell with low fluid velocities.

The Applications of Baffle Plates:

Baffles have a wide range of applications in a variety of industries. They are primarily used in vessels, tanks, and process equipment to control the flow of fluids or gases, improve heat transfer, and prevent undesired mixing. Some common applications of baffles include:

1. Heat transfer: Baffles are used in heat exchangers, boilers, and condensers to increase turbulence and improve the transfer of heat between fluids.

2. Mixing: Baffles can be used to increase mixing and agitation within a tank or vessel, for example, in chemical reactors, crystallizers, and emulsifiers.

3. Separation: Baffles can be used to create barriers within a tank or vessel, separating fluids of different densities or compositions, for example, in oil-water separators.

4. Distillation: Baffles are used in distillation columns to promote the separation of mixture components through their condensation and vaporization.

5. Crystallization: Baffles are used to control crystal growth and promote crystal uniformity in crystallization processes.

6. Chemical reaction: Baffles can be used to create a controlled environment for a chemical reaction, for example, in a reaction vessel.

Overall, baffles are an essential component of many industrial processes, used to enhance efficiency, improve heat transfer, and ensure product quality. The specific application of baffles requires careful consideration of factors such as fluid dynamics, heat transfer, and chemical reactions to ensure optimal performance.

| Selling Units | : | Piece/Pieces |

|---|---|---|

| Package Type | : | Pallet, Ply wooden case |

Packaging: Pallet, Ply wooden case

Productivity: 50 tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: According to Clients' Requirements

Certificate: ASME, U STAMP

HS Code: 8419909000

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,CIP,Express Delivery

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.